Butter Forming Machine: Revolutionizing the Dairy Industry with Milkaya

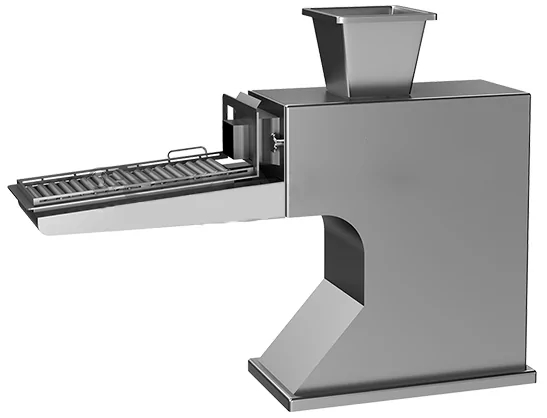

Explore the cutting-edge Continuous Butter Forming Machine from Milkaya revolutionizing butter production with seamless, efficient, and continuous

In the modern dairy industry, efficiency and precision are paramount. For businesses aiming to deliver top-quality butter with consistent shapes and sizes, investing in advanced machinery is no longer a luxury but a necessity. This is where the Butter Forming Machine by Milkaya comes into play. Designed to enhance productivity and streamline operations, this innovative equipment is a game-changer for dairy processors worldwide

What Is a Butter Forming Machine?

A butter forming machine is a specialized piece of equipment used in dairy processing to shape butter into uniform blocks, sticks, or other desired forms. It automates the shaping process, ensuring that each unit is consistent in weight and dimensions, which is crucial for packaging, storage, and distribution.

The machines are equipped with advanced features that enable seamless integration into existing production lines, making them an indispensable tool for small-scale artisans and large-scale manufacturers alike.

Key Features of Milkaya’s Butter Forming Machine

Milkaya takes pride in its commitment to quality and innovation. The butter forming machine offered by the company stands out for several reasons:

1. High Precision and Consistency

Milkaya’s butter forming machine ensures that every piece of butter meets the exact specifications. This level of precision reduces waste and improves overall product quality.

2. Customizable Forming Options

Whether you need butter sticks, blocks, or custom shapes, the machine offers multiple configurations to suit your needs. This versatility makes it ideal for a variety of packaging requirements.

3. Hygienic Design

Made from food-grade stainless steel, the machine complies with international hygiene standards. Its easy-to-clean design minimizes the risk of contamination, ensuring a safe and sanitary production process.

4. User-Friendly Interface

The intuitive control panel simplifies operation, allowing operators to set parameters such as size, shape, and weight with ease. Even those with minimal technical experience can operate it efficiently.

5. Energy Efficiency

Incorporating advanced technology, the machine consumes less energy while maintaining high performance, helping businesses reduce operational costs.

6. Durability and Reliability

Milkaya’s butter forming machine is built to last, with robust components that can withstand rigorous daily use in demanding industrial environments.

Benefits of Using a Butter Forming Machine

1. Increased Production Capacity

Automation significantly boosts production speed, enabling manufacturers to meet high demand without compromising quality.

2. Improved Product Uniformity

Consistency in size and shape enhances the visual appeal of butter products, making them more attractive to consumers and easier to package.

3. Reduced Labor Costs

By automating the forming process, businesses can reduce the need for manual labor, resulting in cost savings and improved operational efficiency.

4. Enhanced Brand Reputation

Producing uniformly shaped butter of superior quality helps establish brand credibility and loyalty in competitive markets.

5. Sustainability

The machine’s energy-efficient design aligns with sustainable practices, contributing to a greener manufacturing process.

Applications of Milkaya’s Butter Forming Machine

Milkaya’s butter forming machine caters to a diverse range of applications, including:

-

Artisanal Butter Producers: Small-scale dairy farmers can use the machine to add a professional touch to their products.

-

Large-Scale Manufacturers: High-capacity operations benefit from the machine’s efficiency and scalability.

-

Specialty Product Lines: The ability to create custom shapes makes it ideal for niche markets and promotional campaigns.

-

Hotel and Catering Industry: Pre-formed butter portions streamline food preparation and presentation.

Why Choose Milkaya?

Milkaya has established itself as a trusted name in the dairy equipment industry. Here are some reasons why businesses prefer Milkaya’s butter forming machine:

1. Proven Expertise

With years of experience in designing and manufacturing dairy equipment, Milkaya understands the unique needs of the industry.

2. Comprehensive Support

From installation to maintenance, Milkaya offers end-to-end support to ensure seamless operation.

3. Affordable Solutions

Despite its advanced features, Milkaya’s butter forming machine is competitively priced, making it accessible to businesses of all sizes.

4. Commitment to Innovation

Milkaya continuously invests in research and development to provide cutting-edge solutions that drive efficiency and growth.

How to Integrate Milkaya’s Butter Forming Machine into Your Production Line

Integrating Milkaya’s butter forming machine into your existing production line is a straightforward process:

-

Assess Your Needs: Determine the volume and types of butter products you wish to produce.

-

Consult Milkaya’s Experts: Get professional advice on machine specifications and configurations.

-

Install the Machine: Milkaya provides installation services to ensure optimal setup.

-

Train Your Staff: Familiarize your team with the machine’s operations through training sessions.

-

Monitor Performance: Regular maintenance and monitoring will keep the machine running efficiently.

Customer Testimonials

“Milkaya’s butter forming machine has been a fantastic addition to our production line. It’s easy to use, and the results are impeccable. Our butter products have never looked better!”

— Sarah L., Dairy Producer

“Thanks to Milkaya, we’ve been able to expand our product offerings and improve our efficiency. The machine is worth every penny.”

— John D., Large-Scale Manufacturer

Final Thoughts

The Butter Forming Machine by Milkaya is a testament to the advancements in dairy processing technology. By investing in this state-of-the-art equipment, businesses can achieve unparalleled efficiency, consistency, and quality in their butter production. Whether you’re a small-scale producer or a large manufacturer, Milkaya’s solutions are tailored to meet your needs.

Take the next step toward revolutionizing your dairy business. Contact Milkaya today to learn more about the butter forming machine and how it can transform your operations.

Frequently Asked Questions (FAQs)

1. What is the production capacity of Milkaya’s butter forming machine?

The production capacity varies depending on the model. Contact Milkaya for detailed specifications.

2. Can the machine handle different types of butter?

Yes, Milkaya’s butter forming machine is versatile and can process various butter types and consistencies.

3. Is the machine compatible with other equipment?

Absolutely. The machine is designed for easy integration into existing production lines.

4. What kind of maintenance does the machine require?

Regular cleaning and periodic inspections are recommended to ensure optimal performance.

5. Does Milkaya provide training for operators?

Yes, Milkaya offers training and support to help your team operate the machine effectively.

What's Your Reaction?

.jpg)

.jpg)